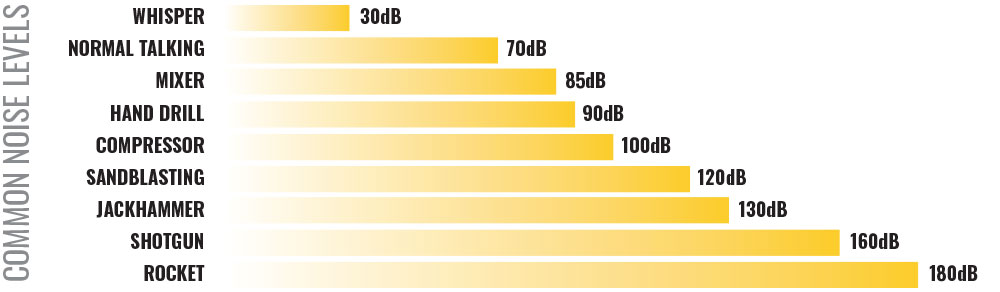

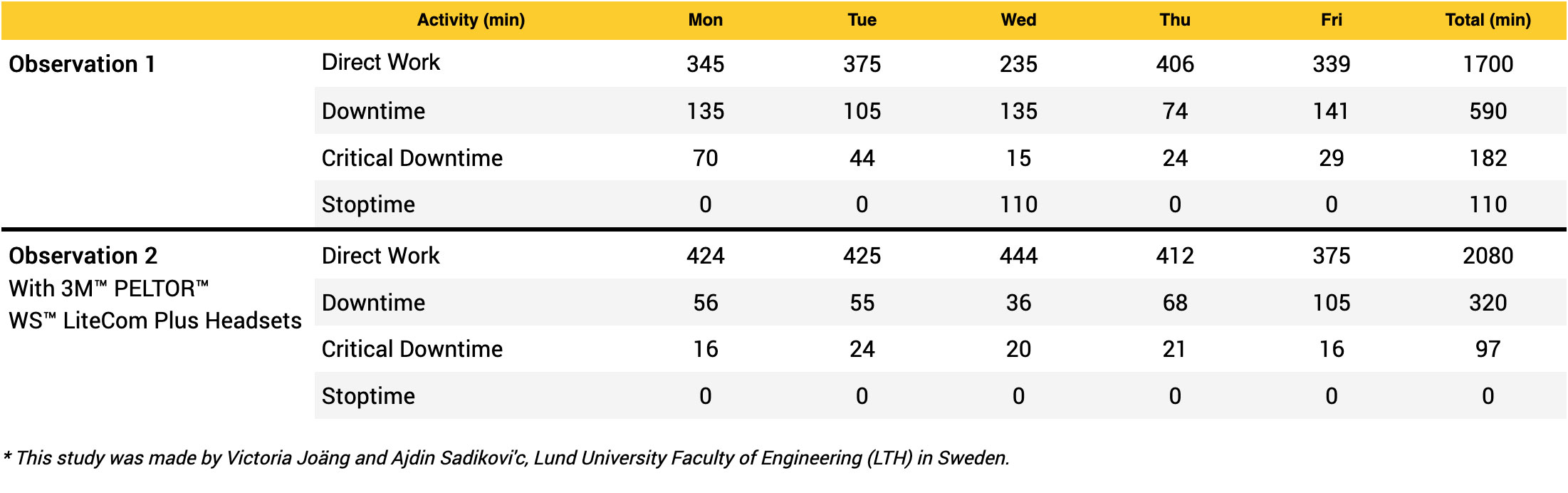

The 3M™ PELTOR™ Professional In-Ear Communication Headset (PIC-100) delivers a personalized on-demand fit test functionality that complies with ANSI/ASA S12.71-2018 and ensures the appropriate protection based on the hazardous noise environment.

Coupled with the ability to enable multiple listeners and simultaneous talkers, this provides a turn-key solution for warehouse, construction, food and beverage, heavy machinery, and manufacturing and transportation workers at the touch of a button.